Custom Designs

Custom made washers for individual applications

The B-TEC Washer Series offers a wide product range as the result of many years of development. Adapted to meet the needs of its users, B-TEC machines provide both practical and economic operating solutions.

Nevertheless, there are still specific requirements B-TEC meets with custom designs – please do not hesitate to contact us!

B-TEC CUSTOM DESIGNS

Industry: Automotive

Requirements: Cleaning of directional air chambers for high rotation atomizers with following testing

Solution: M-1200-WP manual and automatic cleaning and testing station.

The directional air chambers are automatically rinsed with cleaning fluid from the inside. A tilting device allows the cleaning status of the holes to be checked. The manual cleaning station offers the possibility of manual pre- and/or post-cleaning.

Industry: Automotive / Industrial coating

Requirements: Cleaning of stainless steel flow coating cups in special size when using water-based coatings

Solution: RWR-800 special design for separate pre- and post-cleaning.

Based on the B-TEC RWR-800-P, two identical washers were designed for the customer, each of which automatically cleans two cups with lids from the inside and outside.

Industry: Automotive

Requirements: Cleaning of agitator/mixer, container and suction cup gun in one unit

Solution: RWR-800 with individual mounts and spray nozzles.

The spray gun is placed with the suction pipe on a special cleaning nozzle.

A holder enables cleaning of the agitator together with the cover.

A special nozzle arrangement including holder enables separate cleaning of both agitator container and suction cup.

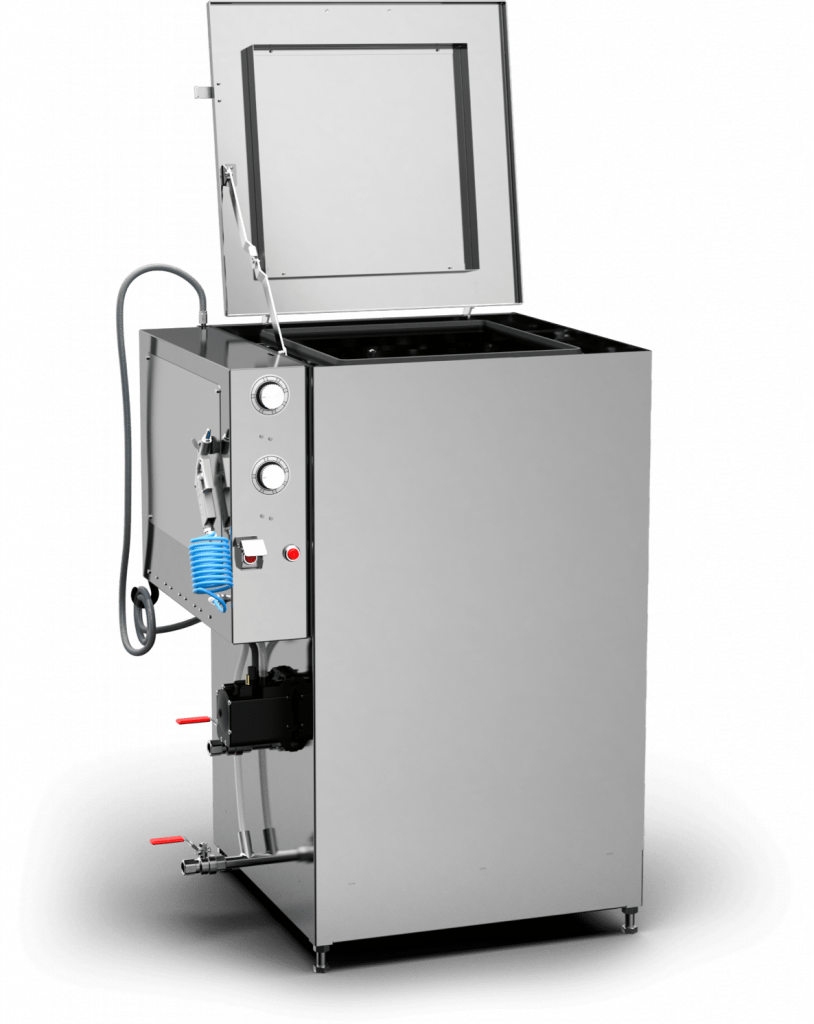

Industry: Aerospace

Requirements: Immersion and cleaning combination unit for parts up to 1000 mm

Solution: M-1200-TW special design with long immersion tank.

Parts to be cleaned can be placed in a large immersion tank and cleaned afterwards or at the same time manually on top of the immersion tank by using flexible gratings.

Immersion baskets with grippers allow easy lifting of the parts from the liquid.

Industry: Chemical industry

Requirements: Simultaneous cleaning of the paint agitator and paint container

Solution: Based on our RWR-800-P, we have designed a washer which, with the help of specially arranged nozzle elements and holders, enables the simultaneous cleaning of the agitator as well as a paint container.