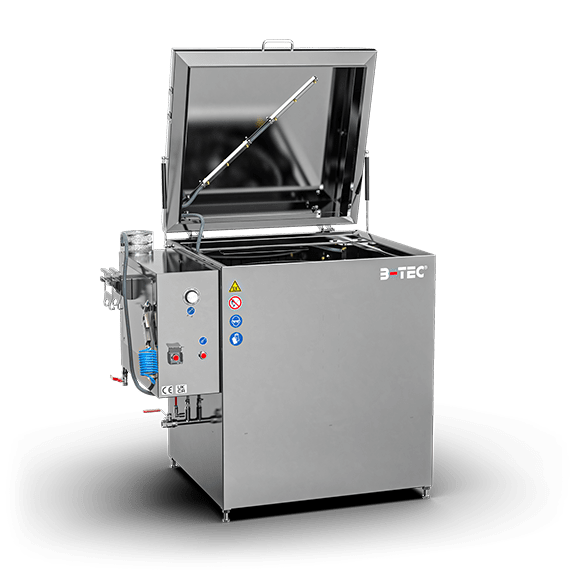

CleanTwist

CleanTwist is the first, entirely pneumatic and ATEX-compliant parts cleaning device with a rotating parts basket – worldwide (patent pending).

With its pneumatically driven rotating basket, CleanTwist can automatically clean (several) (paint-) polluted parts and components up to a size of 590 mm (simultaneously).

Highly flammable cleaning liquids such as 100% acetone are possible.

Compared to static parts cleaning systems (without rotating basket), the rotating basket ensures that each area of the part to be cleaned is evenly wetted with cleaning fluid to achieve a 100% consistent cleaning result.

In addition, CleanTwist can be optionally equipped with our proven automatic clean rinse system to rinse all parts with fresh cleaning fluid again at the end of the automatic cleaning process. This ensures a perfect cleaning result if the circulating fluid is already heavily contaminated. In this way, the circulation fluid can be used for much longer time and highest solvent savings can be achieved.

With the help of the series-standard B-TEC extraction system, hazardous vapours are immediately extracted from the unit as soon as the unit lid is opened.

The user is protected in the best possible way and the contact with solvents is massively reduced compared to time-consuming manual cleaning.

Shortest cleaning times with convincing results

Highlights

- Fully pneumatic, automatic cleaning device for parts cleaning with flammable solvents

- Possible cleaning fluids:

- Highly flammable liquids (category 2, flam. liq. 2):

- GHS/CLP H225, flash point 35°C

- Flammable liquids (category 3, flam. liq. 3)

- GHS/CLP H226, flash point 23°C – 60°C

- Non-combustible, aqueous cleaning agents (neutral or slightly alkaline pH) such as B-TEC H2O Cleaner for water-based paints (B-TEC H2O-Cleaner-RK)

- VOC-reduced cleaner for solvent-based coatings: B-TEC E2C – Easy 2 Clean

- Highly flammable liquids (category 2, flam. liq. 2):

- ATEX-compliant

- shortest cleaning process with excellent results

- automatic cleaning by timer

- removable basket including grippers

- height adjustable basket for specific parts

- basket diameter 597 mm (further sizes possible)

- air blow gun for drying of parts

- fluid drainage pump included

- efficient B-TEC exhaust air system

- Options:

- pump driven flow-through brush

- automatic clean rinse

- Pneumatic exhaust solvent saver, ATEX-Version

PRODUCT ADVANTAGES

suitable for solvents

suitable for solvents

Can be used with solvent and B-TEC E2C.

B-TEC H2O CLEANERS

B-TEC H2O CLEANERS

Can be used with B-TEC-H2O-Cleaners.

ADJUSTMENT Options

ADJUSTMENT Options

All features fully adjustable.

STAINLESS STEEL

STAINLESS STEEL

Bright cleaning chambers due to the utilization of stainless steel. No utilization of light absorbing plastic.

3D View

Technical data

Unit dimensions with closed lid (width × height × depth)

1200 x 1125 x 825 mm

Unit dimensions with opened lid (width × height × depth)

1200 x 1740 x 930 mm

Cleaning basket dimensions (width × height)

597 x 120 mm (individual dimensions possible upon request)

Maximum height of the parts to be cleaned

370 mm

Maximum load capacity of the basket

up to 100 kg