S.U.M.O.

At the S.U.M.O. the name says it all – “Set Up My Own”.

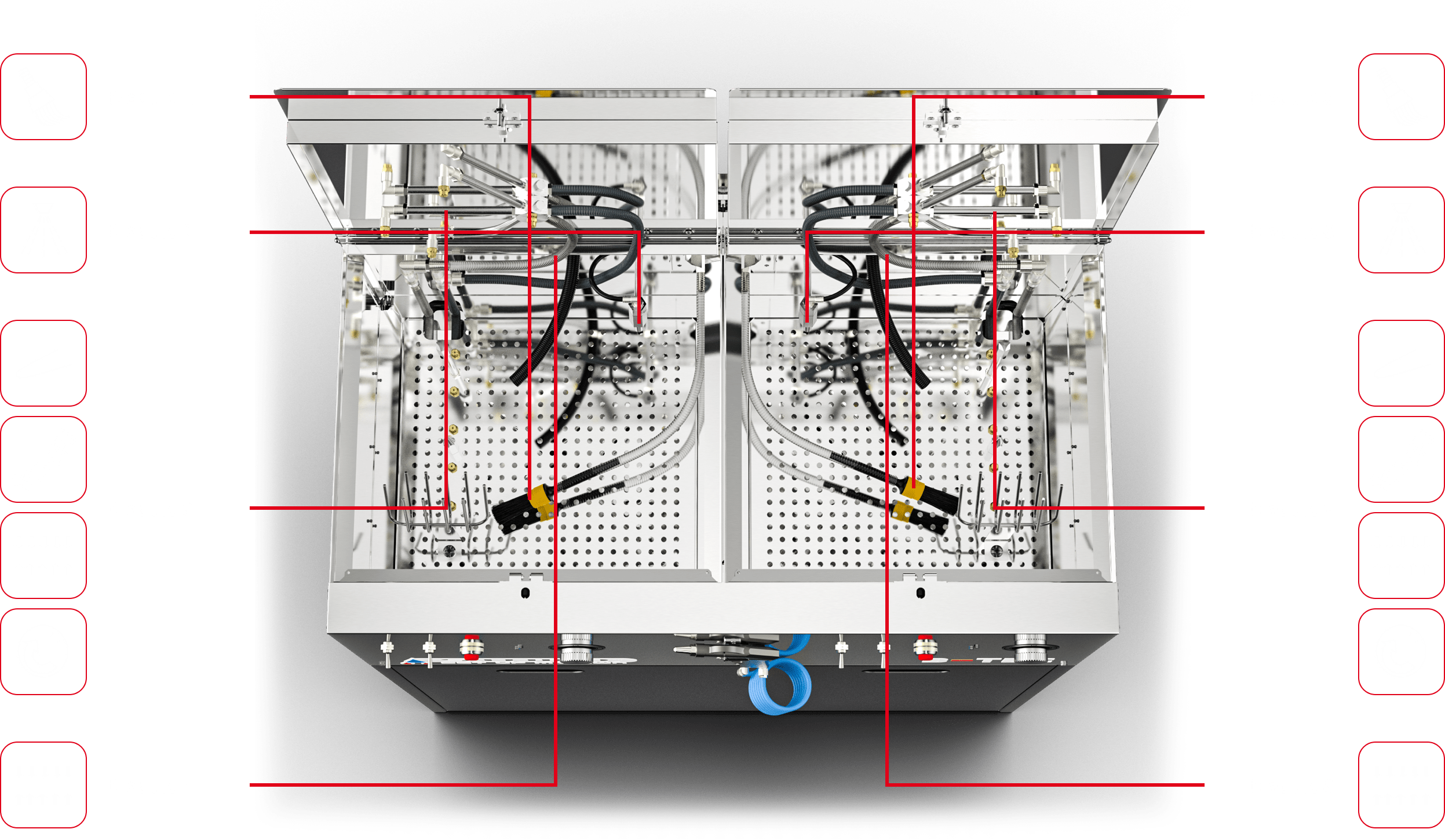

The washer is divided into two independent cleaning rooms, which can be used with solvent / B-TEC E2C, water-based cleaner or each with a different cleaning fluid.

But instead of ordering a completely pre-configured washer, as it is usually the case, we give you the opportunity to equip your own spray gun washer with various functions according to your individual needs.

The basic module of the S.U.M.O. consists of two compact, independent cleaning rooms, includes the familiar powerful B-TEC extraction system for both sides of the machine and an universal blow-off gun.

You can now choose from 9 different modules that include both automatic and manual cleaning features – perfectly matched to your requirements.

You can find an overview of the modules here.

Two generously dimensioned cleaning rooms

Highlights

- Sturdy construction – wall installation possible

- basic module made of stainless steel

- basic module including powerful exhaust air system and air blow gun

- two large cleaning compartments

- pressurized air flow system protects spray guns during the automatic cleaning process

- individual and independent configuration of both cleaning compartments with:

- automatic cleaning with timer

- automatic clean rinse

- pump driven flow-through brush with recirculated cleaning fluid

- manual clean rinse with fresh cleaner

- for solvents, B-TEC E2C and/or B-TEC-H2O-Cleaners

- Options: Pneumatic exhaust solvent saver, ATEX-Version; overflow bund on rollers

PRODUCT ADVANTAGES

suitable for solvents

suitable for solvents

Can be used with solvent and B-TEC E2C.

B-TEC H2O CLEANERS

B-TEC H2O CLEANERS

Can be used with B-TEC-H2O-Cleaners.

STAINLESS STEEL

STAINLESS STEEL

Bright cleaning chambers due to the utilization of stainless steel. No utilization of light absorbing plastic.

ADJUSTMENT Options

ADJUSTMENT Options

All features fully adjustable.

B-TEC air flow system

B-TEC air flow system

Opening of the spray / paint guns by a trigger clamp takes place inside the gun washer after the gun sits perfectly on the cleaning nozzle.

Of course connected to air by the help of the B-TEC air flow system.

Solvent or paint behind the air cap is prevented. No disassembling of the air cap required – less mechanical damage on the paint / spray gun and significant time savings.

Kalrez Diaphragm

Kalrez Diaphragm

With the Kalrez diaphragm our pump is resistant against 1800 different chemicals. Made of corrosion-resistant material, it withstands toughest working conditions in the long term – without a maintenance

requirement.

Configurate your own gun washer

POSSIBLE EQUIPMENT (LEFT SIDE)

Module 1: Pump driven flow-through brush

Module 2: Manual fresh rinse

Module 3: Automatic spray gun cleaning with timer, sealing air purge system and 9 nozzles

Module 4: Automatic clean rinse (only in connection with module 3)

POSSIBLE EQUIPMENT (RIGHT SIDE)

Module 5: Pump driven flow-through brush

Module 6: Manual fresh rinse

Module 7: Automatic spray gun cleaning with timer, sealing air purge system and 9 nozzles

Module 8: Automatic clean rinse (only in connection with module 7)

Module 9: Base with door (galvanized)

Option: Overflow bund on rollers suitable for Module 9

Videos

S.U.M.O. Unboxing and Installation

Spray Gun Cleaning

3D View

Technical data

Unit dimensions including base

(width × height × depth)

900 × 1.480 × 655 mm

Cleaning area dimensions

(width × height × depth)

445 × 270 × 420 mm per side

Material

Cleaning area made of stainless steel, spray nozzles made of brass, base galvanised

Number of paint spray guns at the same time

2

Paint spray gun type

Gravity gun

(other gun types optional)